What is an Air Cooler Float Valve?

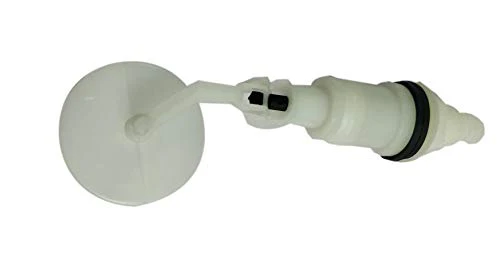

An air cooler float valve is a critical component of an air cooling system, designed to manage and maintain the water level within the cooler. This valve plays a significant role in ensuring the efficient operation of the air cooler by regulating water supply directly into the water tank. Its primary function is to prevent overflow while also ensuring that the cooler operates at optimal moisture levels, which is particularly essential in climates where air cooling is prevalent.

The mechanism of an air cooler float valve is characterized by its ability to automatically adjust the water intake based on the level of water present in the tank. As the water level decreases, the float mechanism lowers, triggering the valve to open and allowing fresh water to flow into the system. Conversely, when the water level rises to a predetermined point, the float rises, causing the valve to close and stopping any additional water from entering. This automatic regulation helps not only in conserving water but also in ensuring that the cooler does not experience operational interruptions due to inadequate or excessive water levels.

There are various types of float valves utilized in air coolers, each designed with specific functionalities and mechanisms. The most common varieties include ball float valves and diaphragm float valves. Ball float valves utilize a buoyant ball attached to a lever system, effectively controlling the valve through mechanical operations. On the other hand, diaphragm float valves employ a diaphragm to manage water flow and pressure, providing a highly responsive solution to water level changes. Understanding these types of float valves is essential for selecting the right one for a specific air cooler setup, ensuring durability and optimal performance.

How Does an Air Cooler Float Valve Work?

The air cooler float valve serves as a crucial component in the functioning of evaporative coolers, playing a key role in maintaining proper water levels. This mechanical device operates on the principle of buoyancy, which is fundamentally grounded in fluid dynamics. As water fills the reservoir of the air cooler, the float—typically made of plastic or other lightweight materials—rises with the increasing water level. This rise triggers the float valve’s mechanism to shut off the water supply when a predetermined level is reached, thereby preventing overflow and ensuring the efficient operation of the cooling system.

When the water level decreases due to evaporation or usage, the float descends, which in turn opens the valve to allow water to refill to the desired level. This dynamic relationship between the float and the valve is essential for the consistent operation of the air cooler, ensuring it effectively cools the air by providing a constant source of water for evaporation.

Should the air cooler float valve malfunction, it can lead to significant operational issues. A stuck float could cause the valve to remain open, resulting in water spillage and potential damage to the surrounding environment. Conversely, if the float gets stuck in the closed position, the lack of water supply would hinder the evaporative cooling process, rendering the cooler ineffective. Understanding the operational mechanics of the float valve is, therefore, essential for anyone looking to maintain or optimize their air cooler’s performance. Regular checks and maintenance of the float and valve are advisable to prevent any such malfunctions, ensuring the longevity and efficiency of the air cooler system.

Common Issues with Air Cooler Float Valves

Air cooler float valves are essential components that regulate water levels within the cooler, ensuring optimal operation. However, like any mechanical part, they can experience issues that impair their functionality and affect the overall performance of the air cooler. One of the most common problems is clogging, which occurs when debris, sediment, or mineral buildup accumulates within the valve. This can restrict the proper flow of water, leading to inefficient cooling and increased wear on other parts of the system.

Another frequent issue with float valves is leaking. A leak can arise from a damaged gasket, loose connections, or wear and tear to the valve itself. Signs of a leaking float valve include water pooling around the base of the cooler or continuous water running into the drainage system. Such leaks not only waste water but can also lead to significant damage to the cooler and surrounding areas if not addressed promptly.

Float malfunctions are also noteworthy concerns. A float valve that is stuck in an open or closed position can prevent the cooler from maintaining the necessary water level. Indicators of float malfunctions include erratic cooling performance, unusual noises from the cooler, or visible movement of the float that does not correspond with the water level. These issues may lead to insufficient evaporative cooling, causing the air cooler to operate less efficiently.

Regular maintenance and inspection are essential to identify these problems early on. Homeowners should be vigilant in monitoring the performance of their air cooler float valves, as early detection can prevent more severe damage to the cooling system. Addressing these common issues promptly not only enhances the efficiency of the air cooler but also prolongs its lifespan.

Maintenance and Troubleshooting Tips

Maintaining the float valve in your air cooler is crucial for ensuring its optimal functioning and longevity. Regular maintenance can prevent common issues and enhance the cooler’s performance. One fundamental practice is to conduct routine checks of the float valve and the entire cooling system. Inspect for any signs of wear or damage, such as cracks or leaks, which can impair functionality.

Cleaning the float valve should also be part of your maintenance routine. Over time, mineral deposits and debris can accumulate, affecting its performance. To clean the float valve, first, turn off the cooler and disconnect it from the power source. Carefully remove the float assembly and use a soft brush or cloth to remove any build-up. If necessary, soak the components in a mixture of vinegar and water to dissolve stubborn deposits, then rinse thoroughly before reassembly. Performing this cleaning procedure every few months can help maintain proper operation.

In addition to routine cleaning, users should be aware of common troubleshooting steps. If the air cooler is not functioning as expected, check if the float valve is stuck or if the water level is too low. A stuck valve may be resolved by gently tapping it to dislodge any obstructions. Occasionally, the float may need adjustment to ensure accurate water level regulation. If you experience persistent issues despite these measures, it may indicate a deeper problem that requires professional assistance.

Recognizing when to consult a professional is essential for maintaining your air cooler’s health. If you are uncomfortable performing repairs or if you identify more complex issues such as electrical problems or significant component damage, do not hesitate to seek expert help. Implementing these maintenance and troubleshooting strategies will not only safeguard the performance of your air cooler but also extend the lifespan of its float valve and other integral components.

When to Replace an Air Cooler Float Valve

The air cooler float valve plays a crucial role in regulating water levels within the cooler, and it is important to replace it when necessary to maintain optimal performance. One of the first factors to consider is the age of the cooler itself. Typically, air coolers have a lifespan of several years, and over time, components, including the float valve, may wear out or become less functional. If the unit is over five to seven years old, it is advisable to inspect the float valve regularly, as wear and tear can lead to ineffective regulation of water levels, resulting in poor cooling efficiency or potential water overflow.

Another critical factor to consider is the frequency of repairs needed for the cooler. If the float valve is frequently malfunctioning or requiring repairs, this may indicate that it is time for a replacement. Continuous issues with the float valve can not only compromise the air cooler’s efficiency but also lead to more extensive problems if left unaddressed. Therefore, keeping track of repair history can provide insights into whether an immediate replacement is necessary.

Lastly, assess the severity of existing issues with the float valve. If you notice that the valve is stuck, broken, or not responding as it should, replacing it promptly can prevent further damage to the air cooler system. When selecting a replacement float valve, it is essential to ensure compatibility with the specific model of your air cooler. Refer to the manufacturer’s guidelines and model specifications to find a suitable valve for optimal functionality. Additionally, pay attention to the installation process, ensuring that the replacement is done correctly and securely to avoid future complications. Proper maintenance, including timely replacements, can significantly enhance the overall performance and longevity of your air cooler.

| Air Cooler Brand Name | Aisen, Arctic, Bajaj, Blue Star, Blueberry, Butterfly, Candes, Cello, Cospex, Croma, Crompton, Crompton Greaves, Cruiser, CRUISER C.S.O., Daenyx, Godrej, Greenchef, HAVAI, Havells, Hindware, Hindware Snowcrest, Impex, Intex, Kelvinator, Kenstar, Khaitan, Krish, Lazer, Lifelong, Livpure, Maharaja Whiteline, Mccoy, Onida, Orient, Pigeon, Polycab, Power Guard, Raptas, Sansui, Singer, Sunflame, Symphony, T-Series, Thomson, Usha, V-Guard, Varna, Vego, Venus, Voltas, Wybor |

|---|---|

| Air Cooler Capacity | 21 to 60 liters, 40 to 80 liters, 60 to 85 liters, Below 20 liters |

| Air Cooler Type | Desert, Personal, Room, Tower, Window |

| Technician Type | With Technician, Without Technician |

Only logged in customers who have purchased this product may leave a review.

Related products

-

Air Cooler Parts

Air Cooler Motor Capacitor

₹390.00 – ₹990.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 0 out of 5 -

Air Cooler Parts

Air Cooler Ice Chamber

₹1,040.00 – ₹1,640.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 0 out of 5 -

Air Cooler Parts

Air Cooler Fan Blade

₹520.00 – ₹1,120.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 0 out of 5 -

Air Cooler Parts

Air Cooler Water Pump

₹910.00 – ₹1,510.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 0 out of 5

Reviews

There are no reviews yet.