Air Conditioner Refrigerant Gas

₹1,899.00 – ₹4,999.00

What is Refrigerant Gas?

Refrigerant gas is a vital component of air conditioning systems, acting as the medium responsible for heat absorption and release during the cooling process. Its primary function is to transfer heat from the indoor environment to the outside, thereby maintaining a comfortable temperature within a given space. This process is achieved through phase changes, where the refrigerant transitions between liquid and gaseous states, effectively harnessing thermodynamic principles to achieve cooling.

In an air conditioning system, refrigerant gas flows through a closed loop, absorbing heat as it evaporates into gas form when passing through the evaporator coil. This cooled gas is then compressed by the compressor, increasing its pressure and temperature. Subsequently, the hot gas moves into the condenser coil, where it releases heat to the outside air and condenses back into liquid. This cycle repeats continuously, maintaining the desired indoor temperature.

There are several types of refrigerants utilized in different air conditioning systems. Commonly used refrigerants include R-22, also known as Freon, which has been widely used in residential air conditioners, and R-410A, a more environmentally friendly alternative that offers enhanced energy efficiency and lower ozone depletion potential. Additionally, natural refrigerants such as ammonia and carbon dioxide (CO2) are gaining traction due to their low environmental impact and sustainability. Each type of refrigerant gas has specific properties, including boiling points and thermodynamic efficiency, that affect its performance and suitability for particular applications.

Understanding refrigerant gas is crucial for anyone interested in the efficiency and effectiveness of air conditioning systems. As technology continues to advance, so too does the development of new refrigerant options aimed at promoting sustainability and reducing greenhouse gas emissions.

Types of Refrigerant Gases

Refrigerant gases play a crucial role in the functioning of air conditioning systems, as they are responsible for absorbing and releasing heat. Over the years, various types of refrigerant gases have been developed, categorized primarily into four main groups: chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), and natural refrigerants. Each type possesses distinct chemical properties and varying degrees of environmental impact and efficiency.

CFCs, once widely used in refrigeration and air conditioning systems, are now largely phased out due to their significant contribution to ozone layer depletion. Composed of carbon, chlorine, and fluorine, CFCs have a long atmospheric lifespan, which exacerbates their greenhouse effects. Industry regulations have resulted in a decline in their usage, marking a shift towards more environmentally friendly options.

HCFCs were introduced as transitional refrigerants to replace CFCs, featuring reduced ozone depletion potential. However, they are still considered harmful due to their greenhouse gas effects and are gradually being regulated as well. This has prompted many manufacturers to seek alternative refrigerants that present lesser environmental risks.

HFCs emerged as popular substitutes for both CFCs and HCFCs, characterized by their lack of chlorine, thus significantly minimizing their ozone depletion potential. Nevertheless, HFCs have been criticized for their global warming potential, leading to ongoing discussions about their environmental impact. Consequently, there is an active movement within the refrigeration industry to transition to natural refrigerants such as ammonia, carbon dioxide, and hydrocarbons. These alternatives showcase not only lower environmental footprints but also improved thermodynamic properties, thereby enhancing system efficiency.

The shift towards more eco-friendly refrigerants reflects a growing awareness and commitment within the industry to promote sustainability and mitigate climate change, showcasing the ongoing evolution in air conditioning technology.

How Refrigerant Gas Works in an Air Conditioning System

Understanding the operation of refrigerant gas is crucial for appreciating how air conditioning systems effectively cool indoor environments. The refrigerant cycle consists of four primary processes: evaporation, condensation, compression, and expansion. Each of these stages plays a pivotal role in the transfer of heat, enabling air conditioning systems to maintain comfortable indoor temperatures.

The cycle begins in the evaporator coil, where the refrigerant absorbs heat from the indoor air. As the refrigerant, typically in a low-pressure liquid state, flows through the coils, it evaporates and transforms into a vapor. This absorption of heat lowers the temperature of the air, producing the cooling effect that we feel within our spaces.

Next, the vaporized refrigerant travels to the compressor, a crucial component of the air conditioning system. Here, the refrigerant gas is compressed, raising its pressure and temperature. This high-pressure gas is essential for the subsequent step of the cycle and prepares the refrigerant for releasing the absorbed heat. Once compressed, the refrigerant moves to the condenser unit, usually located outside the home.

In the condenser, the high-pressure refrigerant gas releases the heat it absorbed earlier. As this happens, the refrigerant condenses back into a liquid form, creating a significant temperature drop. Proper functioning of this stage is paramount, as it ensures that the maximum amount of heat is expelled from the system to the outside atmosphere.

The final process is the expansion of the refrigerant, which occurs when it passes through an expansion valve or capillary tube. This reduction in pressure allows the refrigerant to cool down significantly, returning to its low-pressure liquid state before re-entering the evaporator coil to begin the cycle anew. Maintaining optimal levels of refrigerant gas is essential for the efficiency and effectiveness of the air conditioning system, as insufficient levels may compromise performance and increase energy consumption.

Signs of Refrigerant Gas Issues

Refrigerant gas plays a critical role in the efficient operation of air conditioning systems, and any issues related to it can severely impact performance. One of the most apparent signs of refrigerant issues is insufficient cooling. If an air conditioning unit fails to lower the indoor temperature as expected, it may indicate that the refrigerant levels are low due to leaks or other complications. Individuals may notice that the air blowing from vents is warm or that the system runs continuously without effectively cooling the space.

Another common indicator of refrigerant gas problems is the formation of ice on the evaporator coils. When the refrigerant pressure is incorrect, it can cause the coils to become excessively cold, leading to condensation and subsequent freezing. The sight of ice buildup can be a clear signal of an underlying refrigerant issue, and ignoring it can lead to further damage to the air conditioner. Regular inspections can help in identifying and addressing this issue before it escalates.

Unusual noises during operation can also serve as a warning sign of refrigerant gas problems. Hissing or bubbling sounds may suggest a refrigerant leak, while rattling or clanging noises can indicate internal malfunctions caused by low refrigerant levels. These auditory cues should never be overlooked, as they often reflect the need for immediate attention to ensure the air conditioning system’s longevity and efficiency.

In summary, recognizing the signs of refrigerant gas issues is essential for maintaining an air conditioning unit’s performance. By being vigilant about insufficient cooling, ice buildup, and unusual sounds, homeowners can more effectively identify potential refrigerant-related issues and seek timely repairs or maintenance actions. Addressing these problems promptly can prevent costly repairs and ensure the system operates smoothly for years to come.

Environmental Impact and Regulations on Refrigerant Use

The use of refrigerant gases in air conditioning systems has significant environmental implications, particularly concerning ozone layer depletion and global warming potential. Certain refrigerants, notably chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been shown to contribute to the thinning of the ozone layer, which protects the Earth from harmful ultraviolet radiation. The release of these substances into the atmosphere can have detrimental effects on human health and the environment, necessitating regulatory measures to mitigate these risks.

Recognizing the urgent need to address these environmental concerns, the international community established the Montreal Protocol in 1987, which aimed to phase out the use of ozone-depleting substances. This landmark treaty has led to significant reductions in the consumption of harmful refrigerants, promoting the adoption of alternative compounds with lower global warming potential. As a result, many countries have implemented stringent regulations to limit or ban the use of specific refrigerants in air conditioning and refrigeration systems.

In parallel with these regulations, the HVAC industry is witnessing a shift towards more sustainable practices. Innovations in refrigerant technology have produced options such as hydrofluorocarbons (HFCs) and natural refrigerants like carbon dioxide and ammonia, which pose lower environmental risks. These alternatives not only help in reducing greenhouse gas emissions but also comply with the evolving regulatory landscape.

Moreover, responsible refrigerant management is becoming increasingly important in maintaining compliance with legislation while minimizing environmental impact. Proper handling, recovery, and disposal of refrigerants are essential to prevent leaks and ensure that these gases do not enter the atmosphere unnecessarily. Through proactive measures and adherence to regulatory frameworks, the HVAC industry can contribute to a more sustainable future while continuing to provide effective cooling solutions.

| Brand Name | Amazonbasics, Blue Star, BPL, Carrier, Croma, Cruise, Daikin, Electrolux, Godrej, Gree, Haier, Hisense, Hitachi, Hyundai, IFB, Impex, Intex, Kelvinator, Koryo, LG, Livpure, Lloyd, MarQ by Flipkart, Micromax, Midea, Mitashi, Mitsubishi, Motorola, Nokia, O General, Ogeneral, Onida, Panasonic, Realme, Realme TechLife, Samsung, Sansui, Singer, TCL, Thomson, Toshiba, Trane, Vestar, Videocon, Voltas, Whirlpool, White Westinghouse |

|---|---|

| Capacity | 1 Ton To 1.5 Ton, 2 Ton |

| Type | Inverter Split, Inverter Window, Split, Window |

| AC Refrigerant Gas Types | R22, R32, R410A |

| Gas Cylinder & Bottle Types | Bottle With Technician, Bottle Without Technician, Cylinder With Technician |

1 review for Air Conditioner Refrigerant Gas

Only logged in customers who have purchased this product may leave a review.

Related products

-

Air Conditioner Parts

Air Conditioner Compressor

₹11,999.00 – ₹22,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

Air Conditioner Parts

Air Conditioner Blower Motors

₹3,999.00 – ₹7,199.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

Air Conditioner Parts

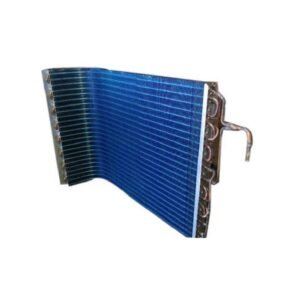

Air Conditioner Condenser Coils

Rated 5.00 out of 5₹19,999.00Original price was: ₹19,999.00.₹18,999.00Current price is: ₹18,999.00. Select options This product has multiple variants. The options may be chosen on the product page -

Air Conditioner Parts

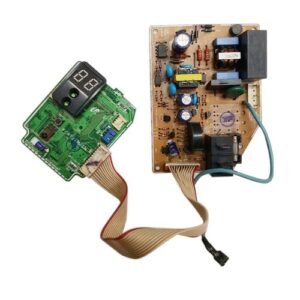

Air Conditioner PCB

₹18,999.00 – ₹22,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5

Manish (verified owner) –

The extended warranty provided excellent protection and quick repair service. Very satisfied with the overall experience.