Air Conditioner Copper Tubing

₹2,299.00 – ₹24,999.00

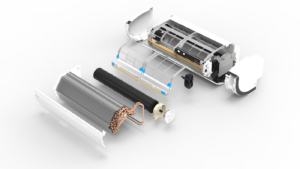

What is Copper Tubing and Its Role in Air Conditioning Systems?

Copper tubing plays a vital role in air conditioning systems, serving as the primary conduit through which refrigerant circulates. This tubing is responsible for transferring heat between the indoor and outdoor units, a fundamental process for maintaining a comfortable climate in residential and commercial spaces. The effectiveness of an air conditioning unit is heavily reliant on the efficiency of its copper tubing, showcasing its importance within the entire system.

One of the standout features of copper is its exceptional thermal conductivity. This property allows it to efficiently transfer heat, enabling the refrigerant to absorb heat from the indoor environment and release it outside, thus cooling the air within. The ability to conduct heat quickly is crucial for the optimal functioning of air conditioning units, ensuring that they can maintain desired temperature levels with minimal energy loss.

Moreover, copper tubing is highly flexible, which simplifies the installation process in various settings. Installers can easily maneuver the tubing around obstacles, potentially reducing installation time and labor costs. This flexibility also aids in accommodating different sizes and configurations required by specific air conditioning systems. Typically, the sizes of copper tubing used in AC installations range from 1/4 inch to 1/2 inch in diameter, with larger systems sometimes requiring larger tubing for enhanced refrigerant flow.

Another important characteristic of copper is its resistance to corrosion. Unlike some other materials, copper maintains its integrity over time, which is essential given the humid conditions often present in air conditioning systems. This resistance prolongs the lifespan of the tubing and the entire air conditioning system, leading to better reliability and fewer maintenance issues. Thus, the choice of copper tubing is not just a matter of efficiency, but also of durability and performance.

Advantages of Using Copper Tubing in Air Conditioning

Copper tubing has long been recognized as a superior material for air conditioning systems, providing several benefits over alternatives such as aluminum or plastic. One of the primary advantages of copper is its remarkable durability. Unlike plastic, which can become brittle over time or aluminum, which may corrode, copper is known for its ability to withstand extreme conditions without significant degradation. This durability ensures a longer lifespan for air conditioning systems, reducing the need for frequent replacements or repairs.

Another notable benefit of copper tubing is its superior thermal performance. Copper has excellent thermal conductivity, which enhances the efficiency of heat transfer within an air conditioning system. This characteristic allows for quicker cooling and faster response times, ultimately leading to enhanced performance of the entire system. When compared to materials like aluminum, which have comparatively lower thermal conductivity, copper’s efficiency can significantly affect the overall energy consumption of the unit, making it a more environmentally friendly choice in the long run.

Furthermore, copper tubing demonstrates considerable resistance to leaks. The joints created in copper systems can be brazed, offering a more robust seal compared to the mechanical joints often used with plastic tubing. This feature minimizes the risk of refrigerant loss, thereby maintaining system performance while also reducing environmental impact. Although the initial investment in copper tubing may be higher than alternatives, the long-term cost-effectiveness becomes apparent when factoring in reduced maintenance costs and enhanced system efficiency.

In summary, the advantages of using copper tubing in air conditioning systems include its durability, better thermal performance, and resistance to leaks. These elements contribute to a more efficient air conditioning setup that, despite a higher upfront cost, proves to be a beneficial long-term investment for both residential and commercial applications.

Installation and Maintenance of Copper Tubing

The installation of copper tubing in air conditioning systems is a vital aspect that directly impacts both functionality and efficiency. To ensure optimal performance, it is crucial to follow proper handling techniques throughout the installation. When starting the installation process, gather the necessary tools, which typically include a tube cutter, a flaring tool, a wrench, and an insulation material. Making precise cuts and flares in the copper tubing is essential, as even minor inaccuracies can lead to leaks and reduced efficiency.

Before initiating the installation, it is imperative to adhere to safety precautions. Always wear protective gear, such as gloves and goggles, to safeguard against sharp edges and metal shavings. In addition, ensure that the work area is free from any hazards that could potentially cause accidents. Properly securing the tubing during installation helps to prevent kinks and bends which can affect air flow and efficiency.

Routine maintenance of copper tubing is equally important in prolonging its lifespan and ensuring continued efficiency. Regularly checking for leaks is a key practice; even a small leak can result in significant energy losses. Employing a standard leak detection solution, such as a soap and water mixture, can help identify any potential issues. In addition, maintaining proper insulation around the copper tubing is crucial, as inadequate insulation may lead to condensation issues that can cause corrosion over time.

Additionally, inspect the tubing for any signs of wear and tear, such as discoloration or corrosion. Promptly addressing any identified issues will minimize the risk of more significant problems in the future. Regular maintenance routines and proactive inspections are central to maintaining the efficiency and reliability of copper tubing, ultimately contributing to the overall performance of the air conditioning system.

Common Problems Associated with Copper Tubing in AC Systems

Copper tubing is a fundamental component in air conditioning (AC) systems due to its excellent thermal conductivity and reliability. However, several common problems can arise with copper tubing that may impact the overall efficiency and performance of the AC system. Understanding these issues is crucial for homeowners and technicians alike.

One prevalent issue with copper tubing is the occurrence of leaks. These leaks can arise from various factors, including improper installation, physical damage, or corrosion. A leak in the copper tubing can lead to a drop in refrigerant levels, resulting in decreased cooling efficiency and increased energy consumption. Detecting a leak might require specialized equipment such as electronic leak detectors, and rectifying it often involves either sealing the leak or replacing the tubing.

Corrosion is another significant problem that can affect copper tubing. While copper is relatively resistant to corrosion, prolonged exposure to moisture and certain chemicals can lead to the development of pits or flakes within the tubing. This corrosion can impede the flow of refrigerant, ultimately impacting the system’s efficiency. Proper maintenance, including regular inspections and ensuring that the tubing is not exposed to harmful substances, can mitigate this risk.

Kinks in the copper tubing are also a common issue, often resulting from improper handling or installation. Kinks can restrict the flow of refrigerant, leading to a drop in efficiency and potential strain on the compressor. Homeowners should be vigilant during installation to ensure that the tubing is correctly bent and not subjected to unnecessary stress.

Addressing these problems requires vigilance and attention to detail. Homeowners should periodically check their AC systems for signs of leaks, corrosion, or tubing deformation. Additionally, working with qualified HVAC professionals can enhance the likelihood of preventing such issues, allowing for a more efficient and reliable air conditioning experience.

Future Innovations and Alternatives to Copper Tubing

The air conditioning (AC) industry is witnessing significant trends towards innovations and alternatives to traditional copper tubing, which has long been a staple material in HVAC systems. With the growing emphasis on energy efficiency and environmental sustainability, manufacturers are actively exploring materials and technologies that can enhance performance while minimizing environmental impact. Among these developments are variations of metals and synthetic materials that could serve as substitutes for copper tubing.

Aluminum is one of the most discussed alternatives due to its lightweight nature and resistance to corrosion. While aluminum has a higher thermal conductivity than copper, advancements in manufacturing processes have significantly improved its performance. Moreover, aluminum is generally more cost-effective and contributes to reduced operational costs, making it a viable alternative for manufacturers aiming to meet consumer demands for affordable yet efficient HVAC systems.

Another innovative direction is the use of expanded polystyrene (EPS) and other foam materials that can insulate effectively without the thermal bridging that often occurs with metallic tubes. These materials also have improved insulation properties that can lead to enhanced energy efficiency, catering to increasingly stringent energy standards across many jurisdictions.

Furthermore, the HVAC industry is beginning to integrate technologies such as smart sensors and IoT-enabled devices. These advancements provide real-time monitoring and data analytics, allowing more precise control over air conditioning systems and optimizing energy consumption. As these technologies mature, they may reduce reliance on copper and other traditional materials by improving overall system performance, regardless of the material used.

Environmental considerations also play a vital role in shaping the future of air conditioning components. Sustainable practices, such as recycling copper and using environmentally friendly materials, are being promoted as critical strategies in manufacturing. In conclusion, the future of air conditioner copper tubing looks promising as the industry embraces innovation and seeks to implement alternatives that enhance energy efficiency and reduce environmental impact.

| Brand Name | Amazonbasics, Blue Star, BPL, Carrier, Croma, Cruise, Daikin, Electrolux, Godrej, Gree, Haier, Hisense, Hitachi, Hyundai, IFB, Impex, Intex, Kelvinator, Koryo, LG, Livpure, Lloyd, MarQ by Flipkart, Micromax, Midea, Mitashi, Mitsubishi, Motorola, Nokia, O General, Ogeneral, Onida, Panasonic, Realme, Realme TechLife, Samsung, Sansui, Singer, TCL, Thomson, Toshiba, Trane, Vestar, Videocon, Voltas, Whirlpool, White Westinghouse |

|---|---|

| Capacity | 1 Ton To 1.5 Ton, 2 Ton |

| Type | Inverter Split, Inverter Window, Split, Window |

| Copper Pipe Units | 10 Feets, 15 Feets, 20 Feets, 25 Feets, 30 Feets, 40 Feets, 5 Feets, 50 Feets, 60 Feets |

| Technician Type | With Technician, Without Technician |

1 review for Air Conditioner Copper Tubing

Only logged in customers who have purchased this product may leave a review.

Related products

-

Air Conditioner Parts

Air Conditioner Refrigerant Gas

₹1,899.00 – ₹4,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

Air Conditioner Parts

AC Remote Control

₹2,899.00 – ₹4,199.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

Air Conditioner Parts

Air Conditioner Evaporator Coil

Rated 5.00 out of 5₹19,999.00Original price was: ₹19,999.00.₹18,999.00Current price is: ₹18,999.00. Select options This product has multiple variants. The options may be chosen on the product page -

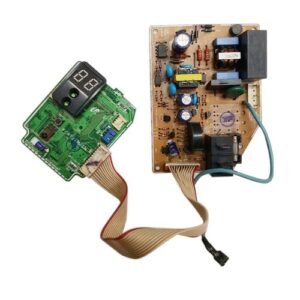

Air Conditioner Parts

Air Conditioner PCB

₹18,999.00 – ₹22,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5

Lalit Kumar (verified owner) –

Great customer service and prompt repair times. The warranty exceeded my expectations.