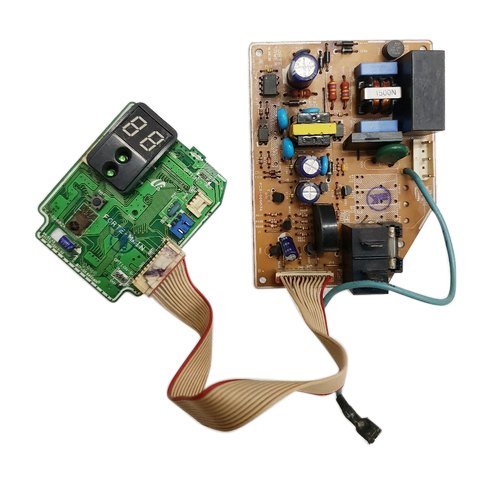

Air Conditioner PCB

₹18,999.00 – ₹22,999.00

Introduction to Air Conditioner PCBs

Printed Circuit Boards (PCBs) play an essential role in the functionality of air conditioning systems, serving as the central hub where various electronic components interconnect. A PCB is a flat board that electrically connects and mechanically supports components such as resistors, capacitors, and microcontrollers through conductive pathways etched from copper sheets. In HVAC systems, the PCB manages the seamless communication between the compressor, fan motors, thermostats, and control systems, ensuring that the air conditioning unit operates efficiently.

The significance of PCBs in air conditioners cannot be overstated, as they are integral to both the control and power distribution within the system. The PCB facilitates not only the operation of the air conditioner but also the monitoring of its performance by relaying signals that indicate temperature, pressure, and general operational status. This interconnected functionality enhances the effectiveness and reliability of HVAC systems, providing comfortable living conditions while maintaining energy efficiency.

Moreover, the quality and design of a PCB directly influence the performance and longevity of an air conditioning unit. A well-designed PCB with superior materials can withstand fluctuations in voltage and temperature, reducing the risk of component failure, which is often a critical issue in HVAC systems. The complexity of contemporary air conditioning systems demands that PCBs are engineered to meet specific operational requirements, thereby emphasizing the importance of implementing stringent quality controls during manufacturing. Ultimately, understanding the role of PCBs in air conditioners enhances our appreciation for their function and the overall efficiency of HVAC systems.

Components of an Air Conditioner PCB

The printed circuit board (PCB) of an air conditioner serves as the fundamental component that integrates various electronic parts to ensure efficient operation. Among the key elements found on an air conditioner PCB are resistors, capacitors, diodes, microcontrollers, and relays, each playing a vital role in the functionality of the HVAC system.

Resistors are utilized to control the flow of electrical current within the circuit, allowing precise adjustments to the voltage levels. By limiting the current, they help in protecting sensitive components and ensuring stable operation. Capacitors, on the other hand, store and release electrical energy, which contributes to stabilizing voltage and filtering out any noise that may interfere with the performance of the air conditioning unit.

Diodes are essential in ensuring the correct direction of current flow. They prevent reverse current that could potentially damage other components on the PCB. This characteristic is particularly crucial in applications where voltage polarity might fluctuate. In combination with these components, microcontrollers act as the brain of the PCB. These programmable devices process information from various sensors, control temperature settings, and adjust fan speeds—all while maintaining optimal performance through user commands.

Relays serve as electrically operated switches that allow the PCB to control larger loads, such as the compressor and fans, without the need for direct connections. This separation is vital for safeguarding the microcontroller from high voltage that could lead to irreversible damage. Together, these components interact seamlessly to ensure that air conditioning systems respond accurately to temperature adjustments and user inputs, ultimately providing comfort and reliability.

Common Issues and Troubleshooting Tips

Air conditioner PCBs (Printed Circuit Boards) play a crucial role in the functionality of HVAC systems. However, like any electronic component, they can face various issues that may lead to suboptimal performance or complete failure. One common symptom of a faulty PCB is irregular cooling. If an air conditioning unit is not cooling as expected, it could indicate that the PCB is not regulating the system correctly. This may be due to improper signals being sent to the compressor or fans.

Another sign of PCB malfunction is unexpected shutoffs. If the air conditioner frequently turns off without reaching the desired temperature, it may be responding to inaccurate readings from its sensors due to a compromised PCB. Error codes displayed on the thermostat or control panel should also be taken seriously, as they can provide crucial insights into the system’s performance and identify potential issues with the circuit board.

For DIY enthusiasts, there are several troubleshooting tips that may help to identify and rectify minor PCB problems. First, check for poor electrical connections. Loose wires or corroded terminals can disrupt the power flow and lead to erratic behavior. Additionally, testing individual components can highlight specific issues. For instance, one might use a multimeter to assess the voltage and continuity of the relays or capacitors linked to the PCB.

It is essential, however, to recognize when to seek professional assistance. Complex PCB repairs or replacements necessitate specialized knowledge and tools, and an improper DIY approach could worsen the issue or create safety hazards. By being proactive and attentive to the signs of PCB problems, air conditioning system owners can ensure their units operate efficiently and reduce the risk of sudden failures.

The Future of Air Conditioner PCB Technology

The landscape of air conditioner PCB technology is evolving rapidly, driven by a range of emerging trends and innovations. One of the most significant advancements is the miniaturization of printed circuit boards. This trend allows manufacturers to design smaller and more compact air conditioning units without compromising performance. As a result, space-constrained environments, such as residential apartments and offices, can benefit from efficient cooling solutions that occupy minimal space while delivering optimal functionality.

Another noteworthy development in air conditioner PCB technology is the integration of smart technologies, particularly the Internet of Things (IoT). With the advent of smart home systems, air conditioning units are now being equipped with PCBs that enable connectivity to the internet. This feature allows for remote control, real-time monitoring, and predictive maintenance, significantly enhancing user experience and operational efficiency. By utilizing IoT-enabled devices, consumers can achieve better energy management and optimize their air conditioning usage based on actual needs, thus reducing both energy costs and environmental impact.

Improvements in energy efficiency continue to be a priority for manufacturers as well. Advancements in PCB materials and designs allow for more efficient energy transfer and reduced power consumption. These efforts are crucial in a climate where energy sustainability is paramount. Furthermore, modern air conditioners equipped with advanced PCBs often feature enhanced performance indicators that aid users in identifying optimal settings for maximum efficiency.

Durability against various environmental factors is another critical area of focus. Enhanced PCB technologies are being developed to resist humidity, high temperatures, and corrosive substances, making air conditioning systems more reliable over extended periods. Investing in robust, weather-resistant materials ensures that air conditioning units can operate effectively even in challenging conditions, decreasing the frequency of maintenance and the need for replacements.

Maintenance and Care for Air Conditioner PCBs

The printed circuit board (PCB) is a critical component of air conditioning systems, governing their functionality and efficiency. To ensure optimal performance and prolong the lifespan of air conditioner PCBs, regular maintenance and care are essential. Various best practices can be implemented to achieve this goal.

One of the primary concerns for the longevity of PCBs is humidity. Excess moisture can lead to corrosion and short circuits within the board, resulting in malfunctions. Therefore, it is imperative to keep the surrounding area dry. If your air conditioning unit is in a particularly humid environment, consider using a dehumidifier to help maintain an appropriate moisture level.

Alongside managing humidity, routine cleaning of the air conditioning unit is crucial. Dust and debris can accumulate on the PCB, obstructing airflow and potentially causing overheating or damage. Regularly inspect and clean the unit’s exterior and ensure that vents are not blocked. If the PCB itself shows signs of dirt, a gentle wipe with a microfiber cloth can help remove contaminants without the risk of damage.

Conducting routine inspections allows for the early detection of any issues that may arise with the PCB. Look for signs of wear, such as discoloration, unusual smells, or visible damage. If any irregularities are noted, it is advisable to consult a professional technician for evaluation and possible repairs.

Finally, it is essential to be aware of when to consider replacing the PCB. If the unit is experiencing frequent failures or inefficiencies despite regular maintenance, replacement may be the most cost-effective solution to restore optimal functionality. Investing time and effort in the care of air conditioner PCBs ultimately contributes to an efficient HVAC system, ensuring comfort throughout its operational life.

| Brand Name | Amazonbasics, Blue Star, BPL, Carrier, Croma, Cruise, Daikin, Electrolux, Godrej, Gree, Haier, Hisense, Hitachi, Hyundai, IFB, Impex, Intex, Kelvinator, Koryo, LG, Livpure, Lloyd, MarQ by Flipkart, Micromax, Midea, Mitashi, Mitsubishi, Motorola, Nokia, O General, Ogeneral, Onida, Panasonic, Realme, Realme TechLife, Samsung, Sansui, Singer, TCL, Thomson, Toshiba, Trane, Vestar, Videocon, Voltas, Whirlpool, White Westinghouse |

|---|---|

| Capacity | 1 Ton To 1.5 Ton, 2 Ton |

| Type | Inverter Split, Inverter Window |

1 review for Air Conditioner PCB

Only logged in customers who have purchased this product may leave a review.

Related products

-

Air Conditioner Parts

Air Conditioner Air Filter

₹1,999.00 – ₹2,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

Air Conditioner Parts

Air Conditioner Thermostat

₹1,199.00 – ₹4,499.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5 -

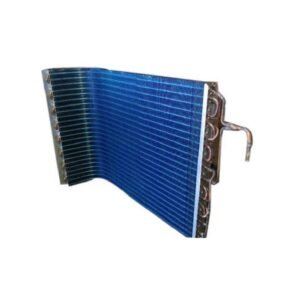

Air Conditioner Parts

Air Conditioner Condenser Coils

Rated 5.00 out of 5₹19,999.00Original price was: ₹19,999.00.₹18,999.00Current price is: ₹18,999.00. Select options This product has multiple variants. The options may be chosen on the product page -

Air Conditioner Parts

Air Conditioner Fan Motor

₹3,499.00 – ₹8,999.00 Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5

Ananya Kapoor (verified owner) –

Fantastic value and protection. The extended warranty was definitely worth the investment.